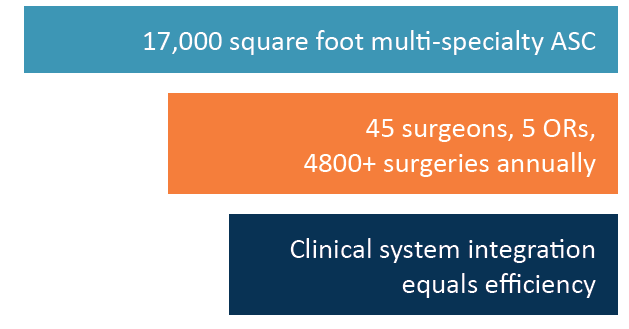

Red Hills Surgical Center provides patient-centered, compassionate and leading edge outpatient surgical procedures performed by 45 local physicians in a 17,000 square foot multi-specialty ambulatory surgery center. The facility is fully accredited through the Accrediting Association for Ambulatory Health Care (AAAHC), which allows measurement of service and performance quality against nationally recognized standards.

THE RED HILLS SURGICAL CENTER STORY

Complex Organization Needed Integrated Solution

Red Hills Surgical Center delivers care in multiple specialty areas, including Gynecology, Orthopedics, Urology, ENT, Podiatry, General Surgery and Pain Management procedures. From a supply chain perspective, this means a wide range of products and a need to understand costs across service lines.

With HST Pathways ASC software as the in-house clinical system, the team wanted to improve efficiency and capabilities. Dan Stannard, RN, CASC, Administrator for the center explained that procurement, item master management and case costing were significant challenges.

“Our goal was to integrate procurement technology with Pathways to ease burden on clinicians, while ensuring we could purchase items at the lowest prices and build visibility to case costing,” said Stannard. Integration efforts with a previous vendor didn’t come to fruition, so Stannard made a decision to move to Envi.

“We’d been operating in two separate systems, and knew interoperability would be the game changer. Envi enabled integration while also advancing us toward other goals including case costing, inventory management and price management.”

The Envi Difference

Stannard set goals to create a more efficient and visible supply chain, covering a broad range of functions. “We’ve been adding new specialty areas, for example, we’re increasing our capabilities in urology. This means we’re quickly adding new items to inventory specific to urology – and we’re using Envi to make sure we get everything added, accurately, with correct vendors and descriptions, at the right price. We use Envi to track depletions and to reflect items on our preference cards, which allows us to do case costing. We’re increasing our capabilities in understanding areas of greater and lower profitability.”

“We now do inventory counts, which we weren’t well-equipped to do previously. Now we print out the inventory list, grab the scanner, and just scan and type. It used to take 5-6 people, 2-3 days for a physical count. Now it’s one of us and it’s done in about a day and a half.”

“Using Envi, it’s easy to handle approvals. We do everything electronically. The workflows in Envi make the process easy, and I use the mobile app for approvals when I’m away from my desk. Now when we receive an invoice, it matches, and we have the freedom to make changes if needed. Envi gives us control, for example, we can update an order for a backorder or partial shipment.”

Envi Drives Best Practices

The Red Hills team has reduced manual workarounds and created greater automation. “We’re not seeing the errors we experienced previously, so we don’t have as much manual intervention,” said Stannard. “The Envi workflow operates well, and helps us stay accurate with prices and units of measure. During the implementation process, we spent time creating an accurate item master with our Envi client team. With our high volume of procedures, there are always new items to add into the item master, and using Envi helps us avoid duplications. Our item add process is streamlined and efficient, and I’m much more confident in our data quality.”

“Now that we’re using an integrated solution, I’m able to look at quantity and pricing data, and can work on better pricing. We’re ordering less inventory, because we’ve gained confidence that the system will work as expected and don’t have to wonder about replenishment dates.”

“We have a better understanding of items and vendors. We have a single number in Envi for an item, and can see all the vendors available to supply that item and the prices. It’s more streamlined to find and purchase items at the best available price, which makes managing inventory simpler too.”

“I encourage people to look beyond what they may be doing today and find ways to do it better.”

Best Practice Award Highlights

- Solution integration between HST Pathways and Envi

- Aligned processes and technology to create automation, reducing staff time

- Envi mobile app to streamline supply management processes

- Barcode scanning to automate inventory counts and ordering processes

- Ensure best pricing on items

- Build processes for ongoing data accuracy, efficient ordering processes

Stannard and the Red Hills team recognize the benefits they drive with Envi, especially case costing. “The interface between Envi and HST provides confidence we have accurate prices in the system. When I run my preference cards to determine what we’ve used, I feel confident everything is up to date and accurate.”

The Case For Change

“For organizations still using manual processes, with printed orders that you call or fax to your vendor, this is a game changer,” concluded Stannard. “We went from hand signing POs to doing everything online. I can catch errors before an order goes out because our approval process is working. Envi gives administrators and managers the authority they need for control.”