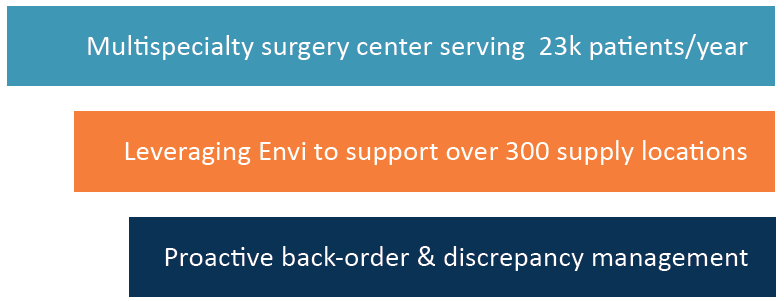

Shifting Supply Chain from Manual to Current

Dan Good was working as a Certified Surgical Technologist when he was asked by Copper Ridge Surgery Center leadership to step into the supply chain role. In a busy facility with a wide range of surgical specialty areas, Good’s clinical training and expertise across the lines of care made him perfectly suited to lead new supply chain efforts.

Now the Supply Chain Manager, Good has had an opportunity to address the early processes of a paper-based supply chain. “We had a 3-ring binder with inventory sheets in them. We’d walk around the facility, circle items and make notes with a marker. I’d go back to my desk, and key everything in. A cumbersome, labor-intensive process. I knew there had to be a better way, which led me to a search for a materials management system that would support our busy center, and also integrate with other systems we have in place.”

Today Envi supports Copper Ridge’s relationships with vendors and other solution providers. Envi’s integration capabilities enable an interface with HST Pathways, and also provides the EDI connection with the primary distributor, helping Good proactively manage a large percentage of supplies. “Most of what we buy comes from our distributor, and the EDI connection makes it easy to manage. We often have 100 line items on a PO. Envi helps identify issues I need to address, like back orders, which are just part of the world we live in today.”

They’ve also enlisted Provista Procurement for contract management support, ensuring Copper Ridge is always connected to current contracts, expiration dates are managed, and price discrepancies are identified and resolved.

Busy Team Supporting 300 Locations

Copper Ridge set up Envi with both ordering and stock locations. “We’ve got 16 pre-op bays, 16 Phase 1 bays and 16 Phase 2 bays, and around 30 carts. We’ve got cabinets, all the endo rooms, locations upon locations – around 300 now in total. Envi helps us manage all these locations. For example, we can easily count everything for our end of the year physical inventory. I print each location, they’re all formatted correctly, and we use scanners to complete the physical count. We save a huge amount of staff time.”

The team works together to manage a highly efficient supply chain, and Good’s clinical background helps him identify and source new products. “I handle the bill only items. Anything that’s ‘walked’ into the building. Also on our team are two buyers, one who manages the OR and another managing the Central Processing Department (CPD), endo and pre/post. Two more team members complete the supply chain staff, one that supports shipping and receiving and another who handles stock and runs items everywhere they need to be.”

“We order and get deliveries throughout the week. We order every other day from our main distributor, and every day on non-stocks. One of the biggest benefits I’ve seen with Envi is time savings. Because we’re a bigger facility, we went from 4-6 hours on ordering to around 2 hours. It’s a huge efficiency.”

In a changing environment, Good has found Envi supports evolving processes. “Today’s supply chain needs a different approach. When I place an order, I want an immediate PO confirmation to know what’s on backorder. There’s been such a shift in supply chain. It used to be relatively manageable to be just in time. Now with supplies often limited, people are anxious to overstock, keep more inventory on hand. It’s harder to know when the next disruption may occur, so people want more on hand.”

Accuracy continues to be vitally important. “In the past, we were taking notes, transcribing, entering data, and mistakes got made. Things weren’t received correctly. You get the wrong item and spend time sending it back. I want to get it right the first time, touch it once, be done with it and move on.”

“We’re much more efficient with Envi. We’re using 3-way matching, one of Envi’s most useful capabilities. By using PO confirmations and inbound receipts to validate that everything ordered was received, we can help ensure invoices – and payments – are accurate.

Envi Best Practice Highlights

- Multiple location management

- EDI Connection with primary distributor

- 3-way matching for invoice accuracy

- Identification of substitute products to replace back-ordered items

- Consolidation of products throughout the facility

Continued Improvement

“The Envi product team has done a really nice job of making consistent upgrades, especially the addition of the dashboards,” concluded Good. “I can see at a glance what my spend is and especially, how much we’re spending in specific areas. Going forward, I plan to expand the way we’re using Envi reporting tools, and also, look at how we can get a better handle on what’s in inventory at any time.”